BOEING 757 AIRCRAFT GENERAL (ATA 5-18) MODIFICATIONS (21)

B737 NG SBAS GNSS Aircraft Integration by Fokker Services

Overview

Fokker Services offers a certified solution for the integration of Satellite-Based Augmentation Systems (SBAS) and Global Navigation Satellite Systems (GNSS), supporting modern navigation, surveillance, and performance-based operations. This upgrade ensures compliance with global mandates while delivering operational efficiency and precision.

LED Logo Light to replace Halogen based logo lights

Talon Aerospace LED logo light Assemblies to replace Halogen replacement.

Do you recognize the following problems with your existing logo lights?

-

Halogen bulbs are replaced frequently

-

Lights are installed in difficult to reach areas and requires use of cherrypicker or lift

-

Lens sealant does not have sufficient time to dry, leading to moisture ingress within horizontal stabilizer

-

Transformer requires frequent replacement

-

Incandescent bulb color temperature changes appearance of corporate logo

Get Light-Years ahead of your competition!

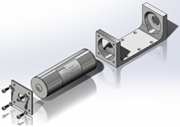

Talon Aerospace LED logo light assemblies are designed to allow for plug and play replacement for the existing HLX64621 halogen bulb based logo lights. Talon uses a rack to replace the OEM logo light housing. The LED module and transformer assembly are mounted to the rack. The OEM aircraft connector is mounted on the transformer assembly, making the LED logo light assembly plug and play.

The lens, lens gasket and hardware can be retained from the OEM unit, but Talon does make replacement lenses available for most applications. The Talon logo light assemblies operate on 115VAC 400Hz aircraft power. A transformer within the assembly steps the voltage down to 14V to power the LED module. All internal connectors are circular mil-spec connectors.

Approved Model List:

- Airbus A320

- Airbus A330

- Airbus A340

- Boeing B737NG

- Boeing 757

- Boeing 777

Planned for Approval:

- Embraer Embraer E170, Embraer E175, Embraer E190, Embraer E195

Talon and Proponent

Proponent is the exclusive global distributor of all Talon Aerospace products.

This relation provides customers with the latest generation of LED lights.

Proponent

Proponent is the new identity representing Kapco Global and Avio-Diepen as one united company, and the unique capabilities that the new organization brings to the aerospace market. With extensive experience in supporting the MRO, OEM and airline markets, our organization offers innovative inventory and supply chain management solutions to OEM and aftermarket customers.

Aircraft Weight and Balance, Loading Schedule, AHM565, Trim Sheet

When introducing new aircraft into your fleet, or changing various items, such as interior layout, cargo layout, certified weights (MTOW/MLW/MZFW), the loading schedule of the aircraft is affected. This introduces changes to the flight envelope of the aircraft in the form of new curtailments for example.

ETOPS 120 minute approval for Boeing 757

Demonstrating the 120-minutes ETOPS capability per AMC-20-6 revision 2 for RB211-535E4-powered Boeing

757-200 series aeroplanes.

Fokker Services iPad® EFB modifications for Boeing aircraft

The EFB Solution for iPad® is a very interesting and cost effective way to introduce an installed classified EFB in your cockpit. An EFB is a physical device containing hardware and software that carries flight documentation. The EFB is used by the flight crew on the flight deck during their duties. Fokker Services’ EFB modification has already been installed in more than 1300 aircraft amongst different aircraft types. Our EFB installation is ticking all the boxes and is available for most aircraft types, including Airbus, Boeing, ATR, Bombardier Challenger & CRJ Family, Embraer, Fokker and others. We can support you with all hardware for your power supply (USB-A and USB-C) and iPad mount (adjustable and pivot mount), our product includes an Engineering Bulletin and all related supplements.

Fokker Services ULD (Underwater Locator Device) for Boeing aircraft

Events related to aircraft missing over oceanic areas have led to several new requirements, amongst which is the introduction of a stand-alone long-range Underwater Locator Device (ULD). Based on this requirement, we are pleased to provide you our offer, which is based on the delivery an integrated package including all related documentation and materials. Note that the ULD is not to be confused with the Underwater Locator Beacons (ULB) as installed on the CVR and FDRs. The ULD is complementary to the ULB and is mounted to the aircraft structure.

Our ULD mod will be mounted on the aircraft structure free of sound absorbent materials and not in wing sections or empennage, we certified multiple locations in a variety of aircraft types. The installation is in accordance with ARINC specification 667, which describes the removal, installation and maintenance aspects of an ULD installation.

Approved Conditions for the Permit to Fly

Under specific circumstances, such as maintenance repositioning flights or check flights—special flight conditions must be defined to operate the aircraft safely and in compliance with regulations.

When a non-EASA aircraft manufacturer issues a No Technical Objection (NTO) or similar statement, EASA requires these be assessed and formalized by a DOA-approved organization before a Permit to Fly application can be submitted.

Engineering Conception Maintenance

With 350 engineers, 45 years of expertise and a large DOA scope, ECM Sky Services assists Airlines in their modification projects with cost effective turnkey solutions. From minor changes to complete VIP cabin design, ECM is a key partner as soon as expertise and reactivity are mandatory.

A project, a request? Please contact us!

The installation of 757 overwater configured aircraft emergency equipment for...

The installation of 757 overwater configured aircraft emergency equipment for sea evacuation. This modification installs two transceivers, two additional ELTs, spare life vests, and associated placards for emergency equipment in accordance with United Air Lines DAS 1 WE Approved Drawing List 2798 dated November 4, 1991 or later FAA approved revision.

Installation of Aerocon Cabin Interior Noise Reduction System

Installation of Aerocon Cabin Interior Noise Reduction System provides passengers a quiet cabin comfortable experience in your aircraft.

Aerocon takes a comprehensive approach to making cabin interiors quiet by providing fully

engineered & documented installation/modified kits. Each kit addresses a specific noise source or

area of the aircraft such as Insulation System Replacement/Modification, Air Distribution System

Modification, Interior Acoustic Treatments, and/or Special Treatments. Configured for easy installation

with clear, simple installation drawings, containing parts sized for easy handling, and utilizing tool-less

mechanical fasteners whenever possible.

Aircraft: B757-200