BOEING 737 NEXTGEN AIRCRAFT GENERAL (ATA 5-18) MODIFICATIONS (30)

AED installation

The use of automated external defibrillators (AED) is essential to increase the chances of survival in case of a cardiac arrythmias such as ventricular fibrillation (VF) and non-perfusing ventricular tachycardia (VT) when used in the first 10 minutes.

AMC1 CAT.IDE.A.220 (b) (4) stipulates that the aircraft operators should carry automated external defibrillator (AED) on board all aircraft equipped with a first-aid kit and required to carry at least one cabin crew.

B737 NG SBAS GNSS Aircraft Integration by Fokker Services

Overview

Fokker Services offers a certified solution for the integration of Satellite-Based Augmentation Systems (SBAS) and Global Navigation Satellite Systems (GNSS), supporting modern navigation, surveillance, and performance-based operations. This upgrade ensures compliance with global mandates while delivering operational efficiency and precision.

LED Logo Light to replace Halogen based logo lights

Talon Aerospace LED logo light Assemblies to replace Halogen replacement.

Do you recognize the following problems with your existing logo lights?

-

Halogen bulbs are replaced frequently

-

Lights are installed in difficult to reach areas and requires use of cherrypicker or lift

-

Lens sealant does not have sufficient time to dry, leading to moisture ingress within horizontal stabilizer

-

Transformer requires frequent replacement

-

Incandescent bulb color temperature changes appearance of corporate logo

Get Light-Years ahead of your competition!

Talon Aerospace LED logo light assemblies are designed to allow for plug and play replacement for the existing HLX64621 halogen bulb based logo lights. Talon uses a rack to replace the OEM logo light housing. The LED module and transformer assembly are mounted to the rack. The OEM aircraft connector is mounted on the transformer assembly, making the LED logo light assembly plug and play.

The lens, lens gasket and hardware can be retained from the OEM unit, but Talon does make replacement lenses available for most applications. The Talon logo light assemblies operate on 115VAC 400Hz aircraft power. A transformer within the assembly steps the voltage down to 14V to power the LED module. All internal connectors are circular mil-spec connectors.

Approved Model List:

- Airbus A320

- Airbus A330

- Airbus A340

- Boeing B737NG

- Boeing 757

- Boeing 777

Planned for Approval:

- Embraer Embraer E170, Embraer E175, Embraer E190, Embraer E195

Talon and Proponent

Proponent is the exclusive global distributor of all Talon Aerospace products.

This relation provides customers with the latest generation of LED lights.

Proponent

Proponent is the new identity representing Kapco Global and Avio-Diepen as one united company, and the unique capabilities that the new organization brings to the aerospace market. With extensive experience in supporting the MRO, OEM and airline markets, our organization offers innovative inventory and supply chain management solutions to OEM and aftermarket customers.

Aircraft Weight and Balance, Loading Schedule, AHM565, Trim Sheet

When introducing new aircraft into your fleet, or changing various items, such as interior layout, cargo layout, certified weights (MTOW/MLW/MZFW), the loading schedule of the aircraft is affected. This introduces changes to the flight envelope of the aircraft in the form of new curtailments for example.

AED Philips Heartstart FRx 861304/Heartsine Samaritan PAD 350

Automatic External Defibrillators (AED) in Aviation Use

Automatic External Defibrillators (AEDs) are becoming increasingly common in daily life. Recognized national health authorities in several countries now recommend the use of AEDs in public and private environments, including aviation.

As a result, operators are being advised by these health institutes to install AED equipment on board aircraft.

To support this initiative, AMC1 CAT.IDE.A.220(b)(4) has been issued, providing additional guidance. This is further explained in EASA FAQ No. 19169, available at: https://www.easa.europa.eu/faq/19169

While AED units are widely certified for civil (non-aviation) use, demonstrating compliance with DOA 160 standards for aerospace applications can sometimes be challenging.

Fokker Services has successfully conducted EMC (Electromagnetic Compatibility) verification testing for the following aircraft types:

-

Fokker 50

-

Fokker 70/100

-

Embraer 170/190

-

De Havilland Dash-8

The testing was performed using the following commercially available AED models:

-

Philips HeartStart FRx (861304)

www.medical.philips.com -

Heartsine Samaritan PAD 350

www.heartsine.com

Certified DE-modification of Obsolete or Custom STC Installations

As part of lease return, phase-out, or aircraft transition processes, removal or reversal of previously installed STCs is often required. These could include obsolete systems, lessee-specific modifications, or customer-tailored configurations no longer applicable for the next operator.

Fokker Services provides certified engineering support for the full demodification process, ensuring compliance, traceability, and airworthiness restoration aligned with the requirements of the new lessee or owner.

TPED tolerance demonstration on B737 aircraft

EASA STC for TPED (Transmitting Portable Electronic Devices) tolerance demonstration on the following B737 aircraft:

- 737-600

- 737-700

- 737-800

- 737-900

- 737-900ER

Fokker Services iPad® EFB modifications for Boeing aircraft

The EFB Solution for iPad® is a very interesting and cost effective way to introduce an installed classified EFB in your cockpit. An EFB is a physical device containing hardware and software that carries flight documentation. The EFB is used by the flight crew on the flight deck during their duties. Fokker Services’ EFB modification has already been installed in more than 1300 aircraft amongst different aircraft types. Our EFB installation is ticking all the boxes and is available for most aircraft types, including Airbus, Boeing, ATR, Bombardier Challenger & CRJ Family, Embraer, Fokker and others. We can support you with all hardware for your power supply (USB-A and USB-C) and iPad mount (adjustable and pivot mount), our product includes an Engineering Bulletin and all related supplements.

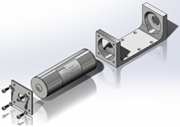

Fokker Services ULD (Underwater Locator Device) for Boeing aircraft

Events related to aircraft missing over oceanic areas have led to several new requirements, amongst which is the introduction of a stand-alone long-range Underwater Locator Device (ULD). Based on this requirement, we are pleased to provide you our offer, which is based on the delivery an integrated package including all related documentation and materials. Note that the ULD is not to be confused with the Underwater Locator Beacons (ULB) as installed on the CVR and FDRs. The ULD is complementary to the ULB and is mounted to the aircraft structure.

Our ULD mod will be mounted on the aircraft structure free of sound absorbent materials and not in wing sections or empennage, we certified multiple locations in a variety of aircraft types. The installation is in accordance with ARINC specification 667, which describes the removal, installation and maintenance aspects of an ULD installation.

Boeing B737-800 (BBJ) Private use to Private & Commercial use

B737-800 from Private use to Commercial.