AIRBUS A320 AIRFRAME SYSTEMS (ATA 20-50) MODIFICATIONS (736)

AOC/ATS Safety Voice SATCOM, ACARS over Iridium and FANS Datalink AFIRS 228

AFIRS™ (Automated Flight Information Reporting Systems) 228 family provides Iridium Global Voice & Data service in real-time, and offer a direct communication link to your aircraft, ensuring safe, secure operations and greater in-flight operational control.

AFIRS™ 228 models are designed and engineered to meet a variety of aviation requirements, such as AOC/ATS Safety SATCOM voice, ACARS over Iridium and FANS datalink.

AFIRS also includes ACARS like services such as automated block and flight times collection and reporting into operational systems, global flight tracking, two-way text messaging (iPad, MCDU), aircraft health monitoring including engine data collection for trending, engine/airframe exceedances, real-time flight data management.

AED installation

The use of automated external defibrillators (AED) is essential to increase the chances of survival in case of a cardiac arrythmias such as ventricular fibrillation (VF) and non-perfusing ventricular tachycardia (VT) when used in the first 10 minutes.

AMC1 CAT.IDE.A.220 (b) (4) stipulates that the aircraft operators should carry automated external defibrillator (AED) on board all aircraft equipped with a first-aid kit and required to carry at least one cabin crew.

ARINC 791 FlightGear™ Ka/Ku Universal Installation

Carlisle Interconnect Technologies, in a partnership with Saint Gobain Performance Plastics, now offers a complete ARINC 791 solution for Ka- and Ku-band SATCOM installations. The complete package contains everything required for either retrofit or forward fit installations on large jet aircraft. Installation fittings are adjustable to cover the complete range of aircraft frame spacing while providing discrete interface loads to the fuselage. The aerodynamic fairing follows the fuselage curvature without requiring a large installation doubler, sealants, or fasteners through the aircraft skin.

B737 NG SBAS GNSS Aircraft Integration by Fokker Services

Overview

Fokker Services offers a certified solution for the integration of Satellite-Based Augmentation Systems (SBAS) and Global Navigation Satellite Systems (GNSS), supporting modern navigation, surveillance, and performance-based operations. This upgrade ensures compliance with global mandates while delivering operational efficiency and precision.

LED Sealed Beam Replacement Lamps for Part 25 aircraft

LED Sealed Beam Replacement Lamps from Talon

Get Light-Years ahead of your competition!

Talon Aerospace sealed beam replacement lamps are designed to allow for plug and play replacement of the existing sealed beam lamps fitted on an aircraft. Talon has 3 sizes available, with replacements for the Par 64 landing, Par 46 taxi and Par 36 logo, runway turn-off, engine and wing scan applications. The existing sealed beam lamps have a design life span between 25 and 300 hours while the Talon LED replacements are designed for 20,000 in service hours.

Light output is comparable to OEM lamps and the Par 64 landing light and Par 46 taxi light are designed to meet Mil Spec standard MIL-L-6503H. The LED replacements work with the existing transformers on the aircraft and are designed to minimize the overall LRU count within an operator inventory. The LED replacement lamps are designed with cool white LEDs to maximize light output but the Par 36 logo is also made available in warm white. Par 36 LED replacement lamps operate on both 13V and 26V AC, while the Par 46 and 64 operate on 26 VAC. All lamps can also operate on 28VDC, allowing for rotorcraft applications.

Talon LED sealed beam are designed at comparable weight to existing sealed beam lamps of equal size, allowing them to be used in existing fixtures. The current draw for the LED lamp is significantly lower compared to the existing units. Landing light Q4559X draws 650W while Talon LED replacement TAE0728-1 draws only 104W.

The LED replacement lamps are fully repairable and operator can replace individual components like the LED board, power supply and lens in case of failures, reducing cost of ownership.

Talon and Proponent

Proponent is the exclusive global distributor of all Talon Aerospace products. This relation provides customers with the latest generation of LED lights.

Proponent

Proponent is the new identity representing Kapco Global and Avio-Diepen as one united company, and the unique capabilities that the new organization brings to the aerospace market. With extensive experience in supporting the MRO, OEM and airline markets, our organization offers innovative inventory and supply chain management solutions to OEM and aftermarket customers.

LED Logo Light to replace Halogen based logo lights

Talon Aerospace LED logo light Assemblies to replace Halogen replacement.

Do you recognize the following problems with your existing logo lights?

-

Halogen bulbs are replaced frequently

-

Lights are installed in difficult to reach areas and requires use of cherrypicker or lift

-

Lens sealant does not have sufficient time to dry, leading to moisture ingress within horizontal stabilizer

-

Transformer requires frequent replacement

-

Incandescent bulb color temperature changes appearance of corporate logo

Get Light-Years ahead of your competition!

Talon Aerospace LED logo light assemblies are designed to allow for plug and play replacement for the existing HLX64621 halogen bulb based logo lights. Talon uses a rack to replace the OEM logo light housing. The LED module and transformer assembly are mounted to the rack. The OEM aircraft connector is mounted on the transformer assembly, making the LED logo light assembly plug and play.

The lens, lens gasket and hardware can be retained from the OEM unit, but Talon does make replacement lenses available for most applications. The Talon logo light assemblies operate on 115VAC 400Hz aircraft power. A transformer within the assembly steps the voltage down to 14V to power the LED module. All internal connectors are circular mil-spec connectors.

Approved Model List:

- Airbus A320

- Airbus A330

- Airbus A340

- Boeing B737NG

- Boeing 757

- Boeing 777

Planned for Approval:

- Embraer Embraer E170, Embraer E175, Embraer E190, Embraer E195

Talon and Proponent

Proponent is the exclusive global distributor of all Talon Aerospace products.

This relation provides customers with the latest generation of LED lights.

Proponent

Proponent is the new identity representing Kapco Global and Avio-Diepen as one united company, and the unique capabilities that the new organization brings to the aerospace market. With extensive experience in supporting the MRO, OEM and airline markets, our organization offers innovative inventory and supply chain management solutions to OEM and aftermarket customers.

Replace Halon by non-Halon fire extinguisher units

New european rule making will be come applicable:

•EASA HalonGuide Nov 2019

•EU: Regulation (EC) No 1005/2009

•EU: Commission Regulation (EU) No 2017/605

and will prohibit the use of Halon filled units per 1 Jan 2026.

Traffic Alert and Collision Avoidance System (TCAS) 7.1

The Traffic alert and Collision Avoidance System (TCAS) is introduced to reduce the risk of mid-air collisions or near mid-air collisions between aircraft. When TCAS II version 7.1 is implemented the probability of mid-air collisions will be reduced significantly. *

The introduction of TCAS change 7.1 software is available for Fokker 50 (SBF50-34-072), Fokker 70 and Fokker 100 A(sbf100-34-105/110) as well as for other types of aircraft like Airbus A318, A319, A320, A321, Boeing 737 series, 757, 767, Bombardier Dash 8 and CRJ. CERTIFICATIONS | Fokker Services Group | Fokker Services Group

Systems from several major vendors are covered in these STS's.

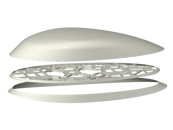

Installation of Invicta Ignition Mitigation / Flammability Reduction in CWT

Press Release June 2021: https://www.jetairegroup.com/post/jetaire-group-provides-faa-airworthiness-directive-exemptions-for-boeing-737-757-767-and-777

On July of 2008, the FAA issued a rule making that makes it necessary for Aircraft manufacturers to provide procedures to reduce flammability for all airplanes with heated fuel tanks located all or partially within the Aircraft fuselage.

CFR Title 14, §26.33 requires installation of a CFR Title 14, §25.981 Amendment 25-125 (or later) compliant Flammability Reduction System (FRS), such as an ‘Inerting System’ or ‘Ignition Mitigation System’ on all Transport Category airplanes with Original Manufacturer Certificate of Airworthiness or Export Airworthiness Certificate issued on or after January 1, 1962.

This Supplemental Type Certificate (STC) is an FAA approved method of compliance (MOC) to the requirements of 25.981 and 121.1117 in the flowing aircraft: B737 - (300 - 900), B757 - (200), and B767 - (200-300).

It is an alternative to the Boeing Nitrogen Inerting System.

Jetaire is the original developer of a foam technology as a means of compliance to 14 CFR 25.981. Jetaire’s INVICTA foam ignition mitigation method kits and components, affecting compliance with 14 CFR 25.981, are patented by the United States Patent and Trademark Office and the unauthorized re-design, use, and/or reproduction of the same is forbidden. These products are exclusive to Jetaire Aerospace, LLC and its rights in the product are protected by law. (U.S. Patent No. 9,849,998, 10,633,109 and 10,800,541).

Airplanes equipped with a Flammability Reduction Means (FRM) approved by the FAA as compliant with the Fuel Tank Flammability Reduction (FTFR) requirements of 14 CFR 25.981(b) or 26.33(c)(1) are exempt from the new Airworthiness Directives, as are airplanes equipped with an Ignition Mitigation Means (IMM) approved by the FAA as compliant with the FTFR requirements of 14 CFR 25.981(c) or 26.33(c)(2). INVICTA is compliant with Ignition Mitigation Means (IMM) and Flammability Reduction Means (FRM) regulations and is the more cost effective and available fuel mitigation system when compared to the Boeing solutions. Jetaire certifies that INVICTA is compliant with the Airworthiness Directives and they hold the Supplemental Type Certificates as follows:

A/C - FAA STC - AD

B737 - ST03450NY - 2020-18-13

B757 - ST04415AT - 2016-07-07

B767 - ST04405AT - 2020-18-16

B777 - In Progress - 2020-18-12

**Jetaire Group is currently in the process of receiving STCs for the B777 and A330 model aircraft.

Jetaire Group specializes in STC-certified and FAA-approved advanced interface systems, and they recently gained their European Union Aviation Safety Agency (EASA) certification and Agencia Federal de Aviación Civil (AFAC) certification for their INVICTA system for the B737 from the Mexican Aviation Airworthiness Authority. They have also received certification from the National Civil Aviation Agency of Brazil (ANAC) for the B737 (300-800) series aircraft.

Installation of Data Loader Connector Panel (DLCP)

The growth of aircraft systems operated by onboard loadable software and the extinction of 3,5” Floppy-Disks make common Airborne Data Loaders (ADL) / Multipurpose Disk Drive Units (MDDU) more and more inconvenient.

Lufthansa Technik (LHT) provides a plug and play Data Loader Connector Panel (DLP) for easy connection of any ARINC 615 Standard Portable Data Loader (PDL). Software Upload effort can be reduced remarkably with a modern Portable Data Loader connected to the Data Loader Connector Panel.